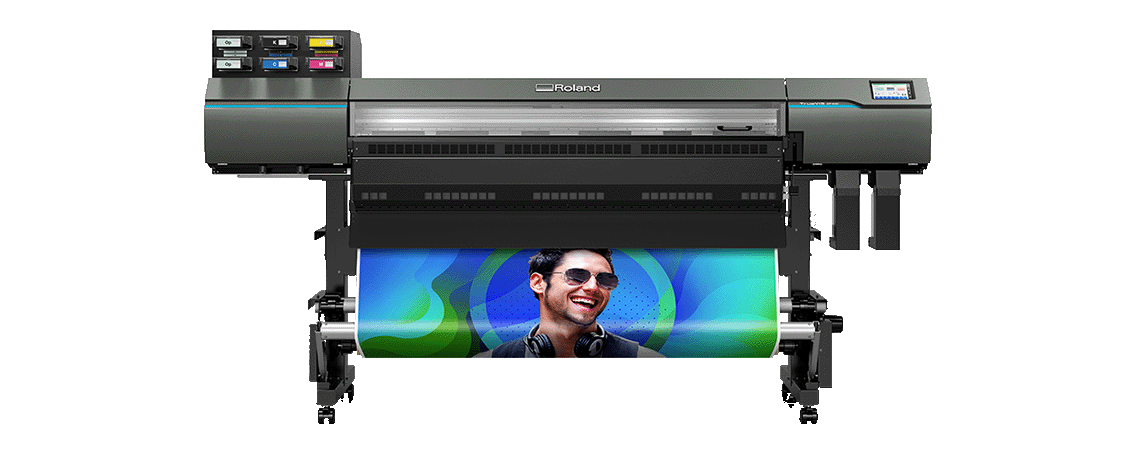

Premium 4-color Resin printer with fast drying inks, excellent durability and optimum usability.

New TrueVIS AP-640 Resin Printer

-

-

FOR MORE DETAILS

Call: +971 4 440 5400

You can also write to us roland@eccdxb.com

Build and expand your sign and graphics business with a wide range of applications, low running-costs, and the quick drying benefits of Roland DG’s first resin printer.

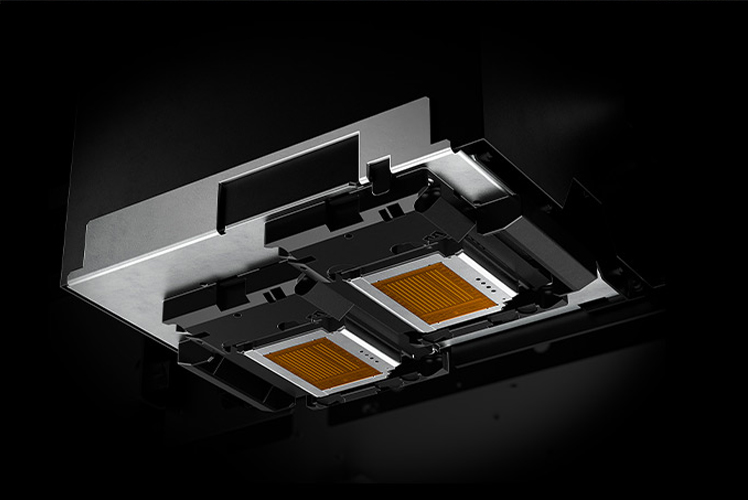

- Dual, staggered printheads with variable dot printing and True Rich Color presets offer natural, vibrant print results with higher color saturation

- Water-based TrueVIS Resin Ink provides quick-drying, scratch-resistant, and safe results on a wide range of media

- Legendary Roland DG machine reliability, service, and support now available in a resin ink printer

Resin Printing Just Got So Much More Vivid and Exciting

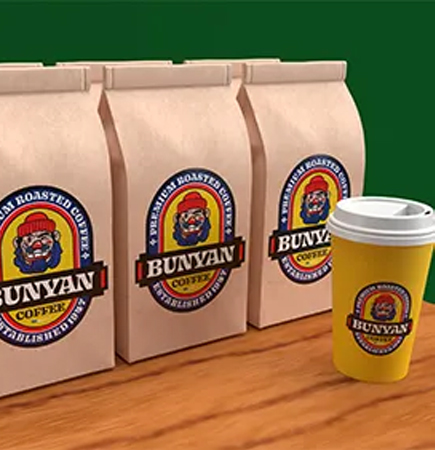

Until now, resin printing was associated with flat, uninspiring color. Enter the TrueVIS AP-640 that’s redefining resin printing with high color saturation on a wide range of materials from uncoated PVC to non-PVC media. It features new TrueVIS resin ink and advanced machine features to optimize color reproduction on vinyl, paper, film, and specially formulated fabrics — expanding your graphics to include flags, roll-up screens, textiles, wallpapers, and so much more.

Floors and More

Wallpaper

Interior Wall Graphics

Labels and Stickers

Fabric and Fine Art

Vehicle Graphics

Print with Extra-Confidence with New Ink Certifications

Global print material providers, 3M and Avery Dennison are now offering warranty coverage for graphics printed with the VG2 and TR2 ink— with Avery Dennison offering warranty coverage for same day print, lamination and wrapping.

What Makes the TrueVIS AP-640 Resin Printer so Amazing?

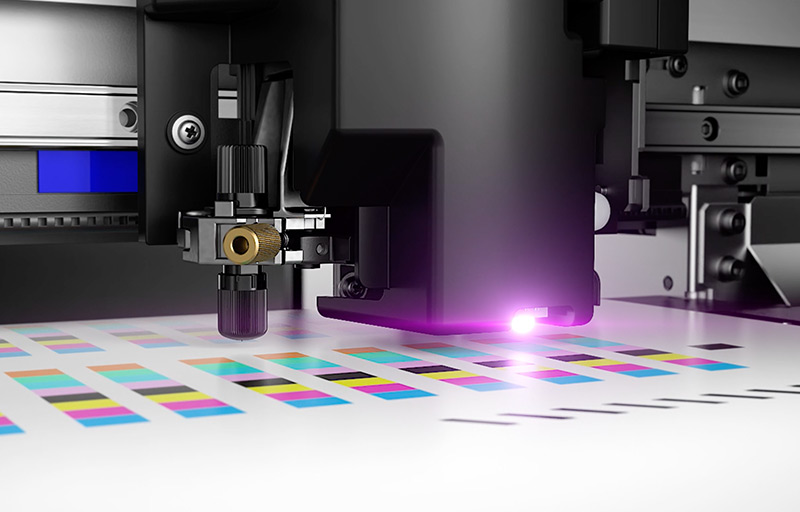

TrueVIS resin printers benefit from hundreds of dedicated, media-specific printing profiles that control optimal ink volume and drying temperature. An optimizer prepares the media surface facilitating the formation of precise dots while variable dot control technology fires three types of ink droplets to create unparalleled image quality, producing natural beauty and vividness never before seen in a resin ink printer.

TrueVIS Resin Ink

The highly concentrated color pigmentation of TrueVIS Resin Ink enables heavier color saturation than conventional resin inks and printers for optimum graphic impact on paper, fabric, canvas, wallpaper, non-PVC materials, and other media.

Safety Comes Standard

With very low VOC emissions, Roland DG resin inks are ideal for interior applications where safety and compliance are the highest priority.

True Rich Color

The True Rich Color preset takes full advantage of the high color saturation of new TrueVIS Ink to maximize print vibrancy and ensure neutral greys, smooth gradations, and natural skin tones.

A 7-inch, full-color touch panel with intuitive settings and functions makes print operations simple. Clearly defined icons for set-up, maintenance, print volume, consumables, print status, and more allow for a convenient, streamlined workflow.

Newly designed drying unit allows prints to dry quickly and completely before proceeding to the next process, saving hours of production time.

|

|

TimeInstant DryingDrying time is virtually eliminated thanks to a built in heating unit. |

|

|

FastSpeed is KeyDual, staggered Piezo printheads receive optimizer and ink in tandem to maintain optimal workflow. |

|

|

700 mlImproved Ink CapacityNew 700 ml high-capacity ink pouches are easily replaceable, supporting economical and environmental printing operation. |

|

|

QualityResin Ink Re-imaginedOur newly developed water-based resin ink and innovative True Rich Color 3 preset works together to ensure vibrant color and natural-looking print quality time and again. |

|

|

SoftwareVersaworks 6The AP-640 comes with user-friendly, feature-filled RIP software, and Roland DG Connect print operation app. |

|

|

SavingsLow Running CostsHigh pigment, quick drying resin inks let you produce more output with less ink, effectively reducing running costs. |

Included VersaWorks 6 RIP Software

The latest edition of the world’s most popular RIP software seamlessly combines with our new AP-640 resin printer technology to effortlessly manage your print output.

Five print queues, five hot folders and unlimited queue settings.

Advanced and easy cropping, tiling, nesting and other features.

New Job Assistant function to layout and edit cut lines in VersaWorks 6 for dual machine print-then-cut workflows.

Match color output between different printers and print modes from a single printer with Printer Color Match Settings that integrate profiling tools such as the i1 Pro3 and new VW-S1 color measuring tool.

Powering the Future of Printed Signs and Graphics

Multi-award winning TrueVIS printers and printer/cutters, now available in a variety of models and print production solutions, have become the benchmark for color quality and performance in the large-format sign and graphics industry. The professional’s choice for building brand consistency, building the highest quality print output, and building confidence in your business, the AP-640 is designed for passionate professionals like you, who need quality, dependability, and versatility to achieve new levels of success.