Built to Fit Seamlessly into a Print-then-Cut Workflow

and Deliver Fast, Flawless Results from Day One

CAMM-1 GR2-640, GR2-540 Large Format Vinyl Cutters

-

FOR MORE DETAILS

Call: +971 4 440 5400

You can also write to us roland@eccdxb.com

Featuring added downforce, precision, and a more intuitive cut operation, CAMM-1 GR2 series large format vinyl cutters were built to work in complete harmony with Roland DG printers. Grow your business with GR2 series vinyl cutters that offer more opportunities to expand your sign and graphics output than ever before.

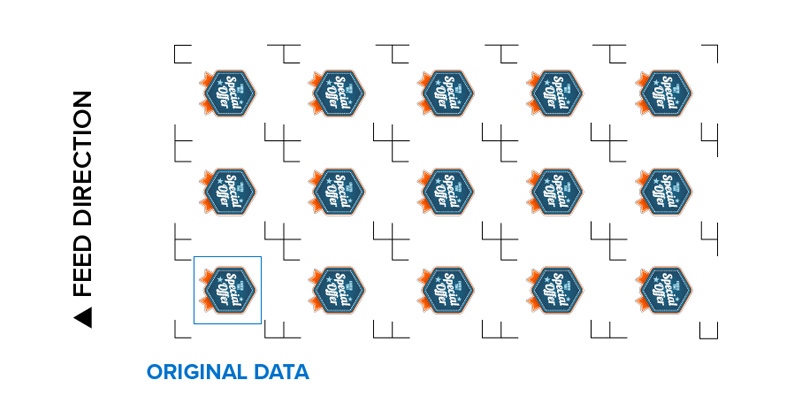

- AAS II Positioning— an intelligent sensor workflow that automatically crops-by-row and repositions for efficient print-then-cut production

- Cutting speeds up to 1,530 mm/s with a downforce of up to 600 gf— cut thin films and thick vinyl with ultimate ease

- New GreatCut-R Software for setting up weed lines, saving job histories, and other dedicated cutting functions

Engineered to Perform, Designed to Combine, Built to Profit

The GR2 vinyl cutter is the perfect choice if you’re a large format printer owner who’s looking to dramatically expand the scope of your business to include print-then-cut applications. It’s also ideal for adding speed and cutting precision to cut only projects. Developed to meet the needs of print professionals in various industries, the GR2 has the functionality for a wide range of products.

Vehicle Graphics

Signs, POP's Displays and Promos

Labels, Stickers and Decals

Heat Transfer Apparel

A More Intelligent Cutting Operation with Roland DG AAS II

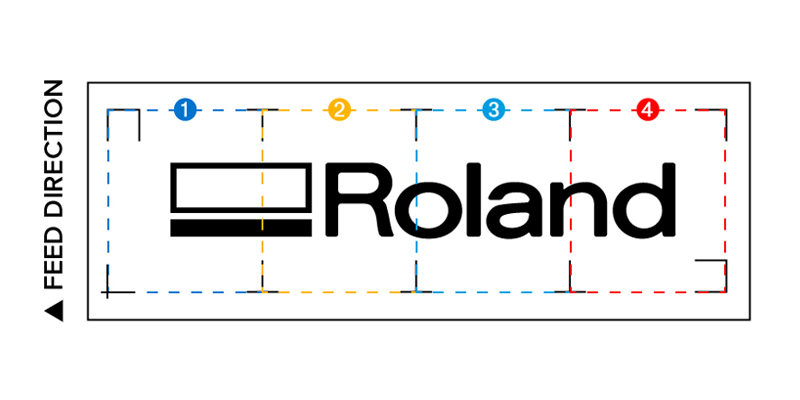

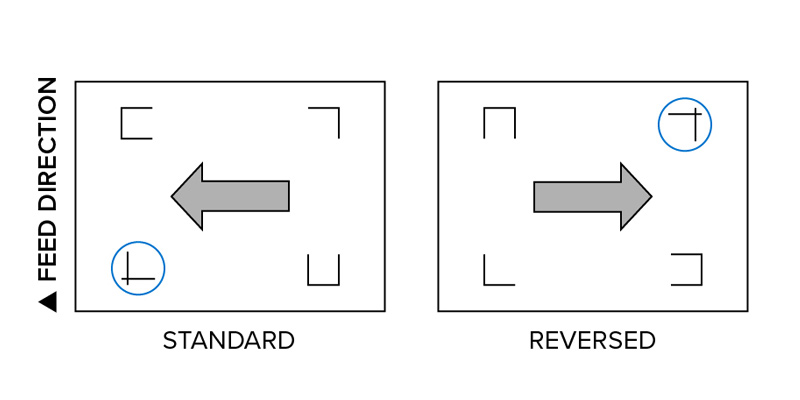

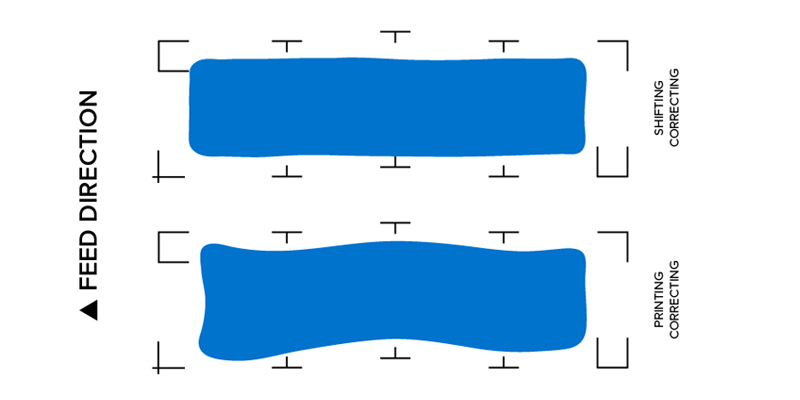

Install the Roland DG AASII positioning function plugin for Adobe® Illustrator® and CorelDRAW® design software to automatically add crop marks to your digitally produced designs. Prep your files with detailed crop mark instructions for a more intelligent cutting and print-then-cut operation in which the AAS II sensor on the GR2 cutter automatically scans crop marks and makes specific cutting adjustments during operation. The following features help you maintain cutting accuracy, especially on long production runs.

Key Features

|

|

Easy integration with TrueVIS VF2-640 and other large-format Roland DG printers using VersaWorks 6 RIP software. |

|

|

Cutting speeds that make a big difference to your business— cut with precision at 1,530 mm/s to increase your graphics output. |

|

|

Reduce production errors with a combination of intuitive software, features, advanced machine sensors and crop-mark detection. |

|

|

A downforce of up to 600 gf expands your media capabilities to include high luminosity reflective sheets, sandblast mask, and other specialty materials. |

|

|

Cut exact with the overcut function that cuts perfect angles and sharp corners when cutting thick material. |

|

|

Immediately expand your sign shop capabilities when you pair your large-format inkjet printer with a GR2 cutter. |

Included GreatCut-R Software

Purchase of the GR2 includes GreatCut-R software with a variety of dedicated cutting functions to support operations, such as setting up weed lines and saving job histories. Designed for the precision cutting capabilities of GR2 technology, you can select different cutting outputs that include “optimal output” to suit your work environment and the nature of your work