MDX-540 Milling Machine Specifications

| MODEL | MDX-540A | MDX-540SA |

|---|---|---|

| Usable Materials | Plastic, resin, wood and non-ferrous metals | |

| XYZ-Axis Travel | 15.7(X) x 15.7(Y) x 6.1″(Z)[400 (X) x 400 (Y) x 155 mm (Z)] | |

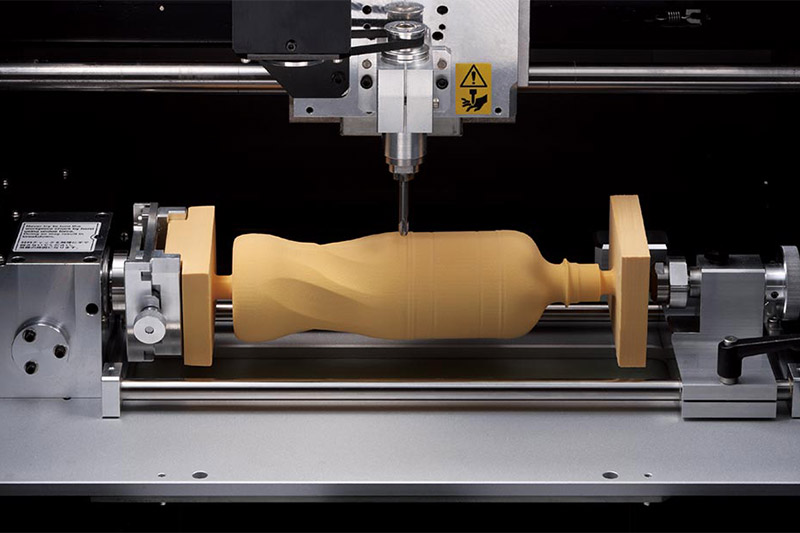

| Loadable workpiece size with optional rotary axis (ZCL-540) * | 7.0” Diameter x 14.6” Length [177.8mm Diameter x 370.8mm Length] Actual milling area is smaller |

|

| Distance From Spindle Nose to Table | Maximum 10″ (254mm) | |

| Table Size | 21.7(W) x 16.5″(D) [550(W) x 420mm (D)] | |

| Loadable workpiece weight | At acceleration of 0.2G: maximum 26lb (12kg), 0.1G: 44lb (20kg), 0.05G: 44lb (20kg) | |

| XYZ-axis drive system | AC servo motor, 60W | AC servo motor, 80W |

| Operating speed | Maximum 295ipm (7.5m/min) | |

| Acceleration | 0.2G, 0.1G, 0.05G | |

| Software resolution | RML-1 mode: 0.0004″(0.01mm ), NC-code mode: 0.00004″ (0.001mm) | |

| Mechanical resolution | 0.00004” (0.001mm) | |

| Positioning accuracy | +/-0.004″/12″(+/-0.1mm/300mm), under no-load conditions | |

| Repeat accuracy | +/-0.0019″(+/-0.05mm), under no-load conditions | +/-0.0008″(+/-0.02mm), under no-load conditions |

| Origin reproducibility (when the power is switched on/off) | +/-0.0019″ (+/-0.05mm) | +/-0.0008″ (+/-0.02m) |

| Spindle motor | DC brushless motor, maximum 400W | |

| Spindle speed | 400 to 12,000 rpm; 400 to 3,000 rpm for positioning and centering | |

| Tool chuck | Tool holder format, Taper shank: JBS4002 15T | |

| Control command sets | RML-1 and NC codes | |

| Interface | USB (compliant with Universal Serial Bus Specification Revision 1.1) | |

| Power supply | Voltage and frequency: AC 100 to 120 V/220 to 240 V +/-10%, 50/60 Hz Required power capacity: 7A (100 to 120V)/4A (220 to 240V) |

|

| Power consumption | Approx. 700W | |

| Acoustic noise level | During operation (no cutting): 65dB (A) or less, during standby: 40dB (A) or less (according to ISO 7779) | |

| Dimensions | Width x depth x height: 29.3 x 37.6 x 33.8″ (745 x 955 x 858mm) | Width x depth x height: 30.1 x 37.6 x 33.8″ (765 x 955 x 858mm) |

| Weight | 249lb (109kg) | |

| Operating temperature | 41 to 104F (5 to 40C) | |

| Operating humidity | 35 to 80% (no condensation) | |

| Included items | Handy panel, power cord, tool sensor, sensor cable, nut, nut wrench, wrench, hexagonal wrenches, Roland Software CD-ROM, SRP Player CD-ROM, User’s Manual, Roland Software Guide, SRP Player Installation and Setup Guide, NC Code Reference Manual, and Automatic Tool Changer (Refer to the ZAT-540 specs below.) | |

| Automatic Tool Changer (ZAT-540) | ||

|---|---|---|

| Number of tools housed | 4 | |

| Maximum tool length | 4.3” (110mm) | |

| Maximum tool diameter | 0.4” (10mm) | |

| Maximum tool weight | 0.77lb (350g) | |

| Tool-holder format | Taper shank: JBS4002 15T | |

| Tool-selection method | Direct-changing type, fixed-address specification | |

| Compatible compressed air | 102 to 145 psi, 1.8CFM (0.7 to 1.0 MPa, 50 L/min or higher) | |

| Spindle speed | 400 to 12,000 rpm; 400 to 3,000 rpm for positioning and centering | |

| Weight | 15lb (6.8kg) (total weight including spindle, magazine, control box, etc.) | |

| Included items | Control box, magazine unit, ATC spindle, air cylinder, base plate, Z-origin sensor, spacer, cap screws, hexagonal wrenches, retaining bands, cable retainers, and user’s manual | |