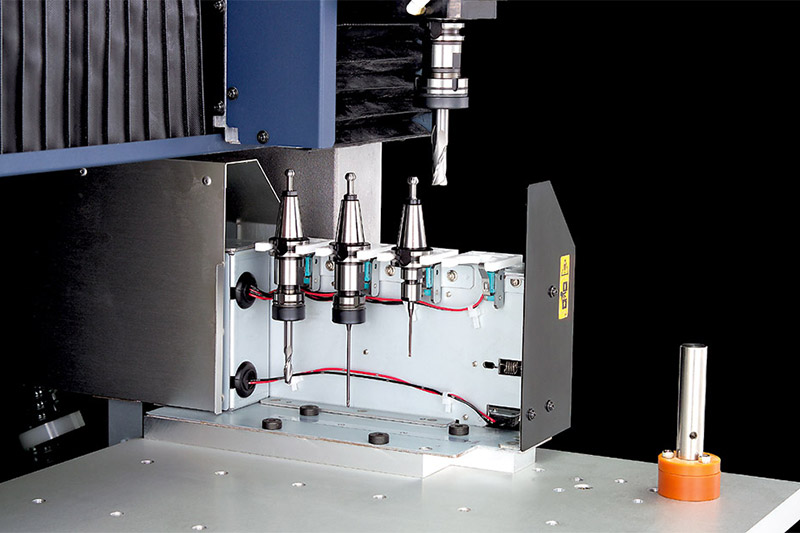

MDX-540 Milling Machine Features

Don't Be Limited by Materials

As a subtractive instead of additive 3D machine, the MDX-540 Rapid Prototype Machine supports a variety of non-proprietary materials that include ABS, nylon, hardwood, plywood, FDA approved resins, non-ferrous metals and much more. The following items are just some of the prototypes and applications that are possible with this versatile device:

Molds for casting

Toys and games

Product prototypes

Furnishings and decorations

Electrical parts and casings

Relief signs and graphics

Make Prototypes with Fit and Function

The MDX-540 Rapid Prototype Machine can be used to produce functional prototypes and proof of concept testing for industrial and commercial release, such as thermal and structural trials. Used extensively by engineers, the MDX-540 is ideal for creating aluminum, brass and copper molds for rapid injection molding and EDM electrodes for production tooling. Plus, MDX-540 parts meet a host of FDA and other government regulations.

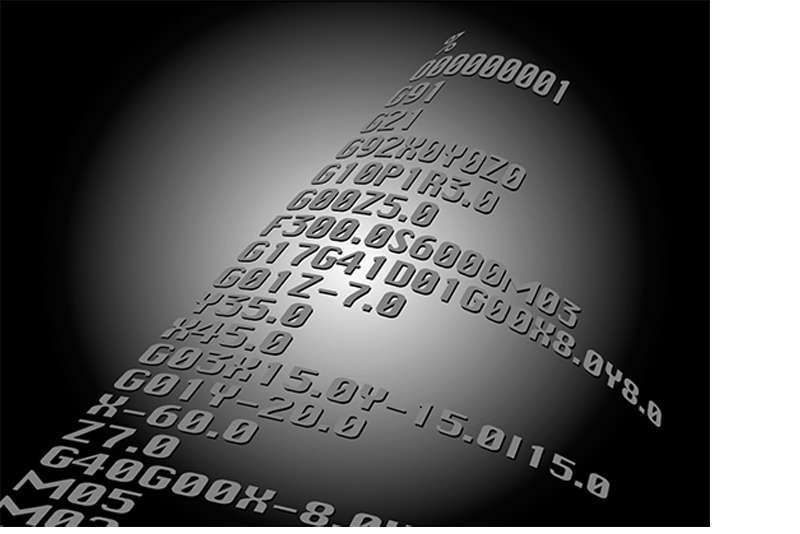

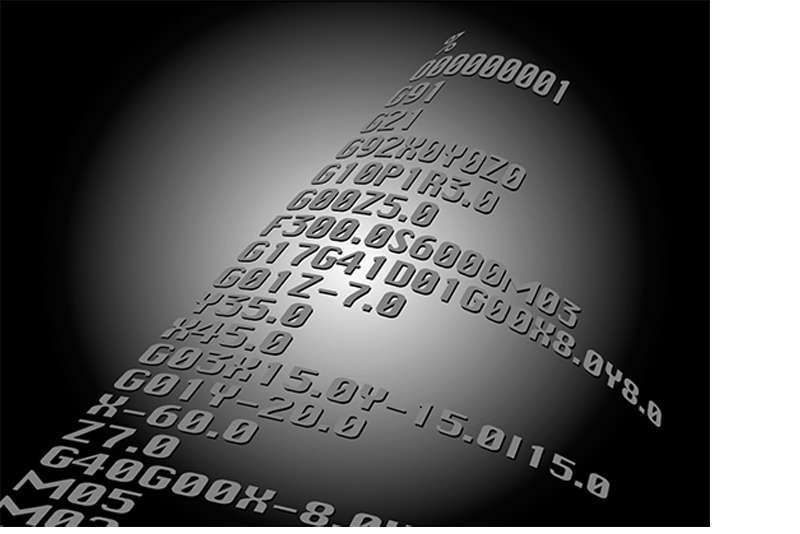

SRP Player CAM Software

G-Code Support

Mill Fast and Smooth for Minimal Finishing

Stay In-Control with a Hand-Held Controller and Virtual Control Panel

Your Machine, Your Configuration

Quality and Reliability are Standard

Roland DG international ISO certifications are your guarantee of superior quality.