![]()

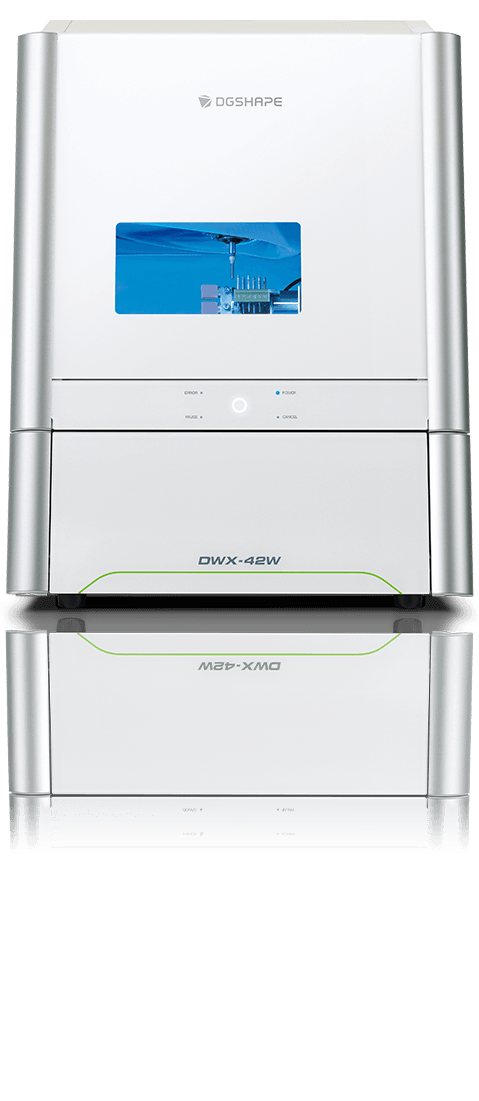

Intelligent Machine.

Effortless Production.

Superior Results.

From in-clinic to dedicated high-production labs, the DWX-42W is engineered to fit your milling needs.

DWX-42W Wet Dental Mill

-

-

FOR MORE DETAILS

Call: +971 4 440 5400

You can also write to us roland@eccdxb.com

The DGSHAPE DWX-42W enables wet milling of popular glass ceramic and composite resins with high precision and accuracy.

- High speed production with proprietary DGSHAPE spindle

- Expanded 6-tool Automatic Tool Changer for uninterrupted milling

- LAN capable for easy connectivity

- Included VPanel for easy monitoring of milling jobs and tools

Incredibly Accurate, High Esthetic Restorations

Materials

Composite Resin

Superior margins and chip resistance

Glass Ceramics

Consistent flexural strength, optimized fit

A Mill That Fits Your Needs

High Production Lab

- Expand production by adding a standalone wet-milling option, designed for glass ceramic and composite resin materials

- Get the same open architecture flexibility and high-quality performance as DGSHAPE dry mills, in a wet-milling configuration

- Offer on-demand production of high-esthetic, dental prosthetics

![]()

In-Clinic Lab

- Offer your patients a same day service with ultra-accurate prosthetics – produced with an easy-to-operate machine and simplified workflow

- Open architecture allows seamless integration with existing scanning devices

- Designed to combine with the DGSHAPE d-CLINIC solution

![]()

Specially Designed Spindle

- 50% LESS Air Pressure Needed

- Designed and built by DGSHAPE— using over 35-years of cutting-edge engineering excellence

- A robust, all-metal spindle offers solid performance and maximum efficiency

- Doesn’t require a high-volume compressor— perfect for in-clinic labs

Elevated Performance

50% FASTER

than previous generation DGSHAPE wet mill

6-STATION AUTOMATIC TOOL CHANGER (ATC)

for uninterrupted production

Newly Designed

NOZZLES AND COOLANT TANK

for greater flow and capacity

Specially Engineered

DUAL FILTERS

require replacement less often, saving cost and time

Brand new burs offer

GREATER STABILITY & FINE MILLING QUALITY

Enhanced User Experience

![]()

New Ethernet LAN Connectivity

Access your device and manage your milling, anywhere in the lab or office.

![]()

Upgraded V-Panel

Complex controls are replaced with an easy interface to monitor milling jobs and tool life.

![]()

CAM Software Included

Easy-to-use, open architecture CAM software accepts all STL files and supports the milling of relevant materials.