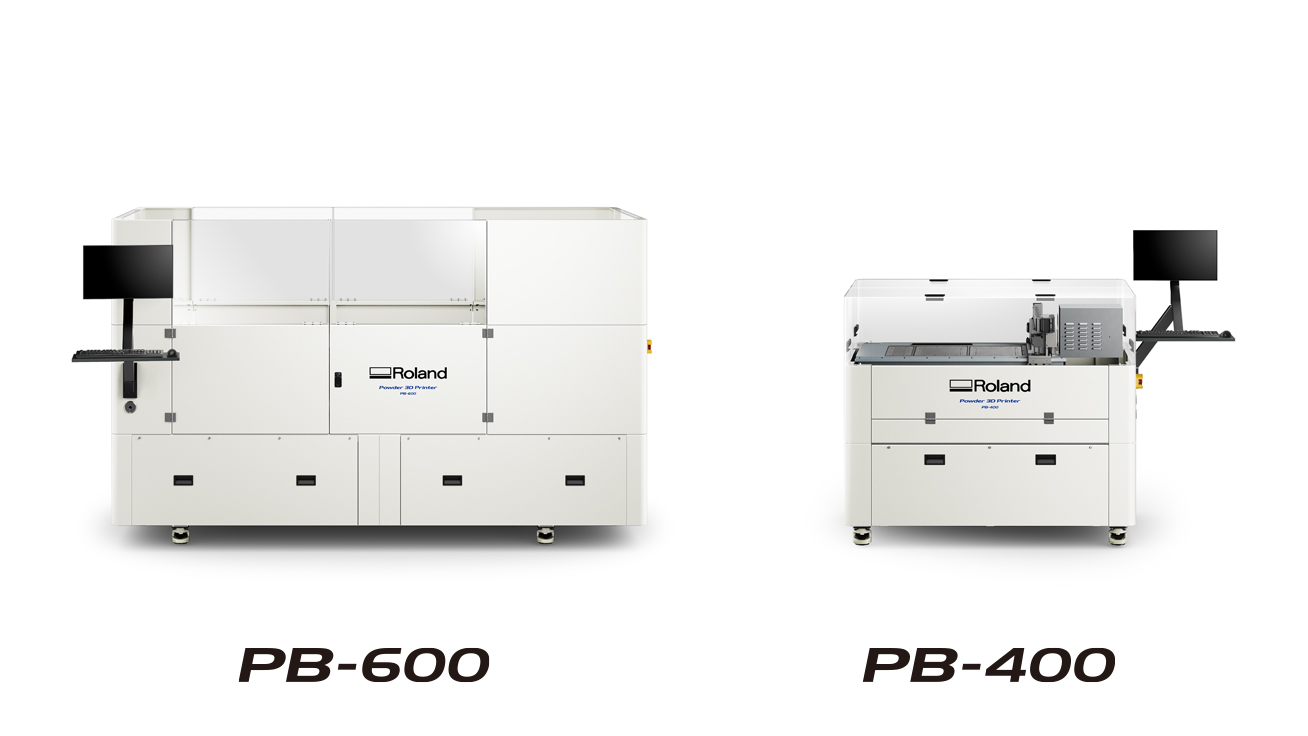

Roland DG Corporation, a developer and distributor of digital solutions such as commercial inkjet printers and compact 3D processing machines, is pleased to announce the release of two new powder 3D printers, the PB-600 and PB-400, which make it easy for anyone to create ceramic products, which normally require special skills and know-how.

The PB series is a 3D printer that creates three-dimensional objects by stacking special powder one layer at a time using a liquid binder that is sprayed from the print head to solidify it.

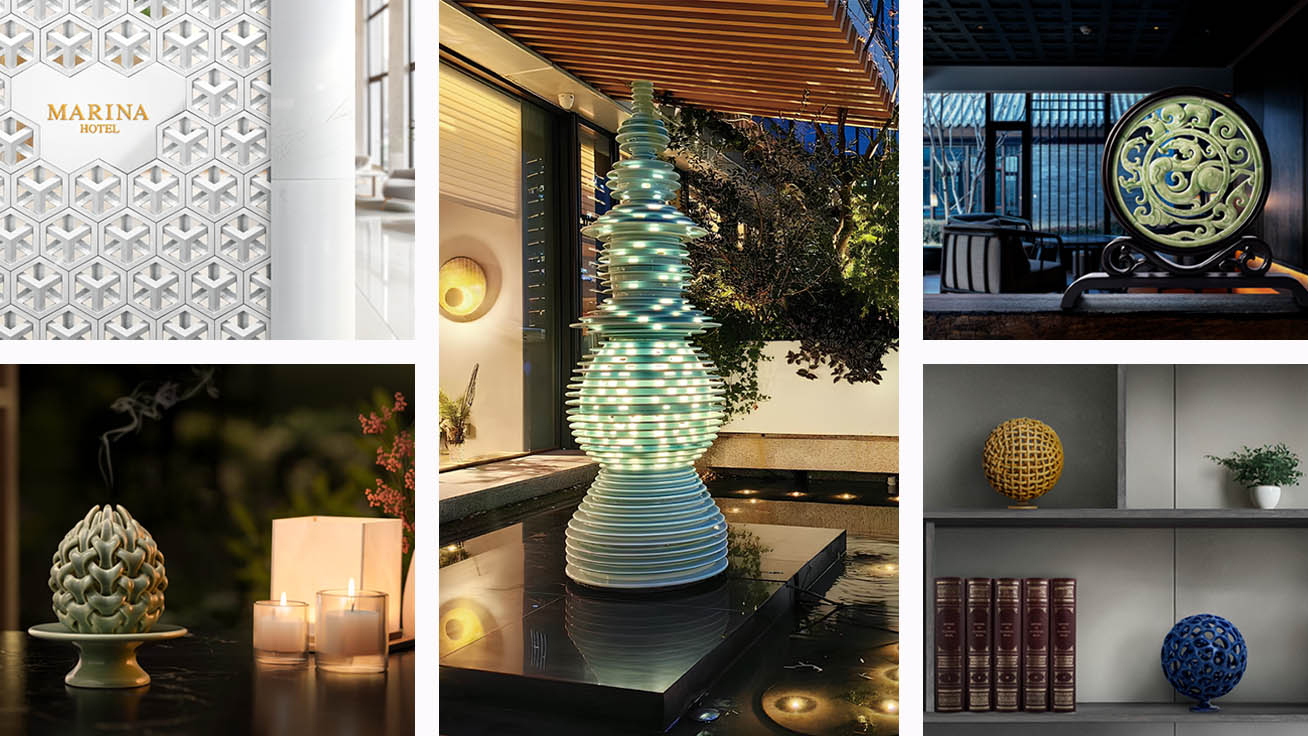

The special powder used is made from the artificial ceramic “BRIGHTORB®.” Anyone can now create and reproduce ceramic products with complex shapes that only a select few craftsmen could create before, as well as artistic interior objects, ceramic panels, ceramic walls, and even replicas of fine arts and crafts and earthenware that are difficult to create by hand.

In addition, BRIGHTORB® has excellent performance with fine particles and a shrinkage rate of only 1% or less after firing. Furthermore, the PB series layers this fine material at an optimal thickness, allowing complex objects to be finished with high precision, beauty, and smoothness.

The modeling area is up to 595 (width) x 600 (depth) x 250 (height) mm for the PB-600, and up to 390 (width) x 290 (depth) x 200 (height) mm for the PB-400. By laying out multiple objects in a three-dimensional layout, you can efficiently create not only large objects but also small objects at once.

In addition, slicing software that converts 3D data of objects created with 3D CAD or 3D CG software into output data is included as standard. The printer can also be intuitively operated from the monitor attached to the product body, so even first-time users can use it with confidence.

Ryugo Futamura, Head of the Global Sales & Marketing Division, said, “Since our founding in 1981, we have supported the digitalization of a variety of industries by providing digital devices that turn ideas into reality. The PB Series is a solution that leverages the unique characteristics of 3D printers to enable people to create unique, premium three-dimensional objects with their own hands, unlike anything seen before. It has the potential to revolutionize traditional processes in the interior decoration industry, as well as in fields such as architecture, art, fine arts, and crafts, and even in education and research institutions in areas such as history and culture, while greatly expanding the possibilities of expression and bringing new value and business. We would like to continue to contribute to creating an environment where people can fully express their infinite creativity through our innovative digital solutions.”

The PB series will be available in Japan, Taiwan, and the ASEAN region from today, with sales areas to be expanded thereafter.

Application image

Main Specifications

| Product Name | PB-600 | PB-400 |

|---|---|---|

| Modeling method | Binder jet method | |

| XY Resolution | 600×600dpi | |

| Layer Pitch | 0.1mm | |

| Build speed | 35 seconds/layer | 45 seconds/layer |

| Build size | Maximum 595 (width) x 600 (depth) x 250 mm (height) | Maximum 390 (width) x 290 (depth) x 200 mm (height) |

| Powder Materials | Ceramic Powder | |

| External dimensions/weight | 3,150 (width) x 1,344 (depth) x 1,900 (height) mm / 1,200 kg | 1,709 (width) x 970 (depth) x 1,382 (height) mm / 430 kg |

| power supply | AC 230V single phase 16A | |

| Standard price (unit)* | Open Price | |

| Release Date | Sales will begin around the world on January 29, 2025. | |

*Total price including main unit and software, excluding shipping and installation fees