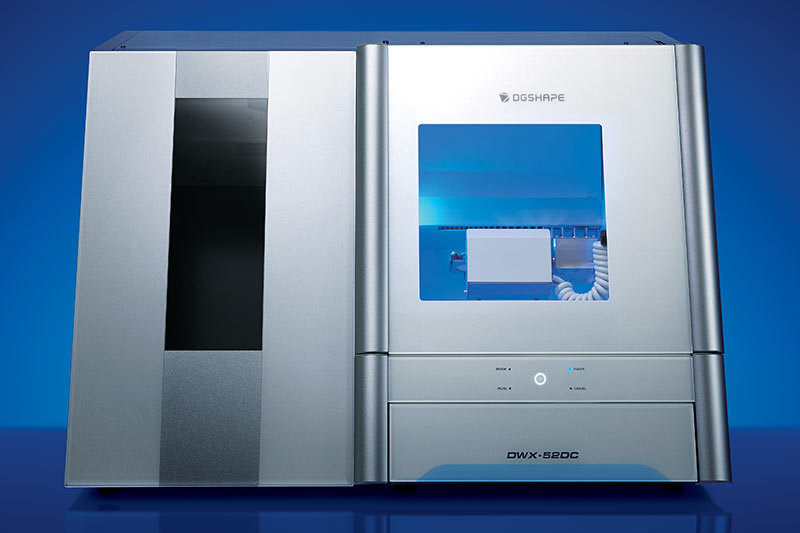

DWX-52DCi Dental Milling Machine Features

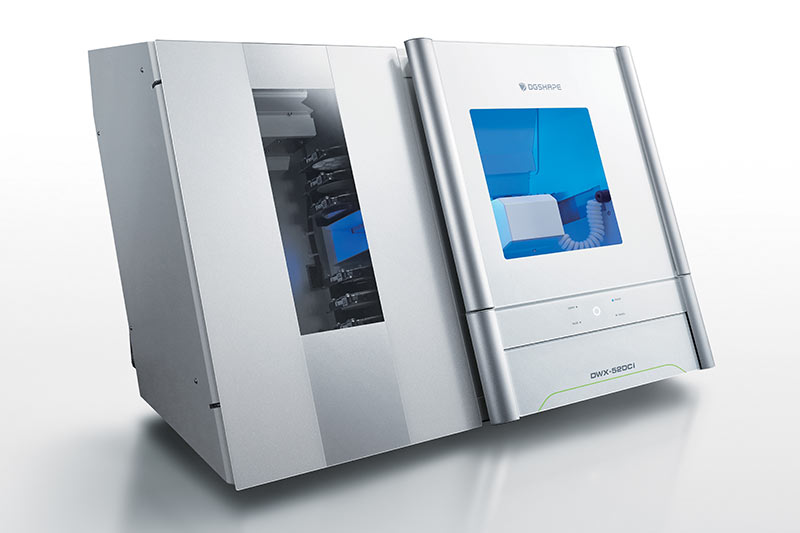

Automatic Disc Changer (ADC)

Load the six material adapters with different shades of zirconia or any combination of material discs to suit your needs. Assign them with milling jobs and let the automatic disc changer do the rest.

The adapter system enables multi-device adapter integration. The same material adapters can be milled on both the DWX-52DCi and DWX-52D for a convenient and scalable milling solution.

Automatic Tool Changer (ATC)

Load the 15-station ATC with a variety of diamond coated, carbide and DGSHAPE by Roland hybrid tools to continuously mill jobs in different materials and multiple shades of zirconia without stopping production.

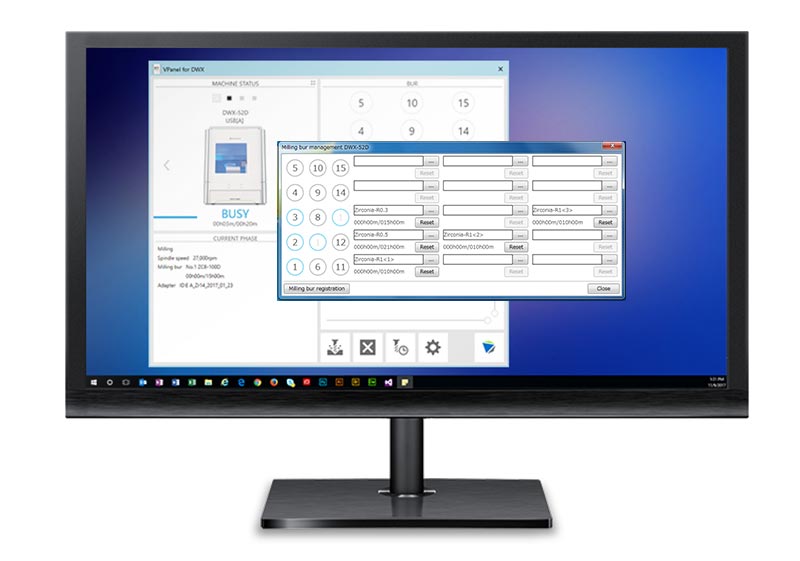

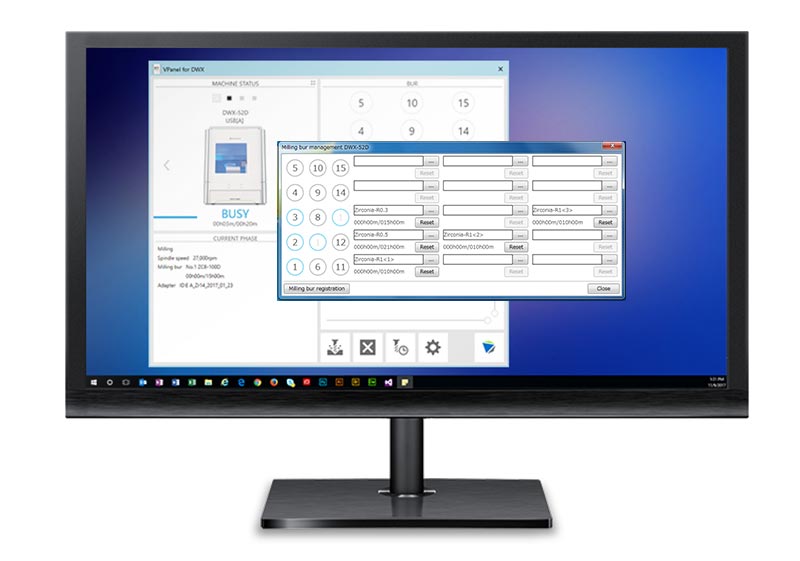

Intelligent Tool Control

Part of the simplified VPanel operation, an Intelligent Tool Control (ITC) function automatically swaps out tools that have reached their user-defined lifespan with a designated “partner tool” without needing to pause production.

5-Axis Milling

A smooth and steady ball screw-driven system provides superior milling results – simultaneously rotating and tilting discs for deep undercuts and also milling large arch restorations and other full-mouth prosthetics.

Automatic Air Pressure Control

An automated regulator eliminates the need for manual air control adjustments by changing air volume based on material data via the CAM software.

Intuitive Software for Added Milling Control

The DWX-52DCi features new DWINDEX software that enables users to plan, identify and manage indexing operations to assert improved control over the machine productivity. It offers data accumulation and analyzation for the following key features:

- Operation time per tool

- Operation time per disk

- Operation time of the unit (day/week/month)

- Error log

- History of materials used

- History of deliverables

User Replaceable Spindle

The DWX-52DCi features a spindle that can be replaced in a matter of minutes, without needing to call out a technician. No special tools, testing or training is required.

A Clean, Precise and Flexible Milling Solution

Simplified Operation with VPanel Upgrade

The upgraded user-friendly Virtual Machine Panel (VPanel) automatically swaps out used burs (ITC function), conducts machine diagnostics, and offers one-click machine calibration. New and improved features include user-defined ATC tool positioning, advanced email notifications for maintenance and milling status, and machine management for up-to four DWX-52DCi units at once.

Upgraded Cleaning and Dust Collection

Keep a clean operation by loading a brush tool into the Automatic Tool Changer (ATC) to automatically sweep away milling debris, while an internal dust collection system and ionizer reduces milling static. A new, upgraded dust collection system automatically starts when opening the front cover to keep dust away from your lab surfaces and to support a clean and healthy environment.

Open Architecture

The DWX-52DCi gives you the freedom to work with your choice of the latest CAD/CAM software, scanners and materials. Users are not tied to a single software or proprietary control source.

*Contact your Roland authorized dealer for the open architecture set-up that’s right for you.

Optional Accessories to Optimize Production

Included disc adapter rack allows users to cue-up and keep materials organized for an even more efficient workflow. |

|

Included pin adapter for holding up to eight pin-type blocks |

|

Add additional adapters for quick insertion and optimum workflow |

Optional carbide, diamond and hybrid milling tools (0.3mm, 0.6mm, 1.0mm, 2.0mm) |

|

Optional BOFA DustPro vacuum unit to remove material waste during milling |

Highest Clinical Standards

The DWX-52DCi is made in Japan as a Class I medical device. With meticulous build quality and in accordance with the highest Japanese industrial standards, it gives users added assurance should any medical compliance laws change.

Warranty and Support

DGSHAPE by Roland ensures that your machine is always up-and-running with a one-year warranty plus support from a network of dedicated dealers and certified service engineers. From our helpful customer support team to an abundance of training and education, Roland cares about your customer needs before and after machine purchase.

![]()

Peace-of-Mind Reliability and Support

Roland has been at the forefront of advanced machine manufacturing for 30 years, providing practical and reliable technology with unmatched service and support.

DGSHAPE by Roland further delivers on this reliability promise but also improves user experience, making it incredibly easy for labs to produce high quality, cost effective dental prosthetics while improving workflow efficiencies.