Follow this Quick Tip to improve ink adhesion to challenging surfaces by encapsulating your graphic.

UV ink can print to almost any surface, but that doesn’t necessarily mean it will do so with a high level of adhesion on all surfaces. For instance, when UV ink is printed to glass, acrylics, or other smooth surface media, achieving optimum adhesion can be challenging.

The first thing to consider when UV printing on any surface, including the types of substrates that make it difficult for ink to adhere to, is that a clean static- free surface will allow the ink to print and hold to the surface better.

Recommended:

When printing on tougher surfaces, we recommend wiping the product with an anti-static, cleaning solution, such as 409 Multi-Surface Cleaner, an alcohol-water mix, or simply a general purpose anti-static spray

Once the surface is clean, it’s typically a good idea to prep your media with an adhesion promotor prior to printing. There are a lot of options when it comes to promoters, but for a general promoter that works well in a wide variety of cases, we recommend SEM XXX. This spray can be found online or at a general hardware store.

-

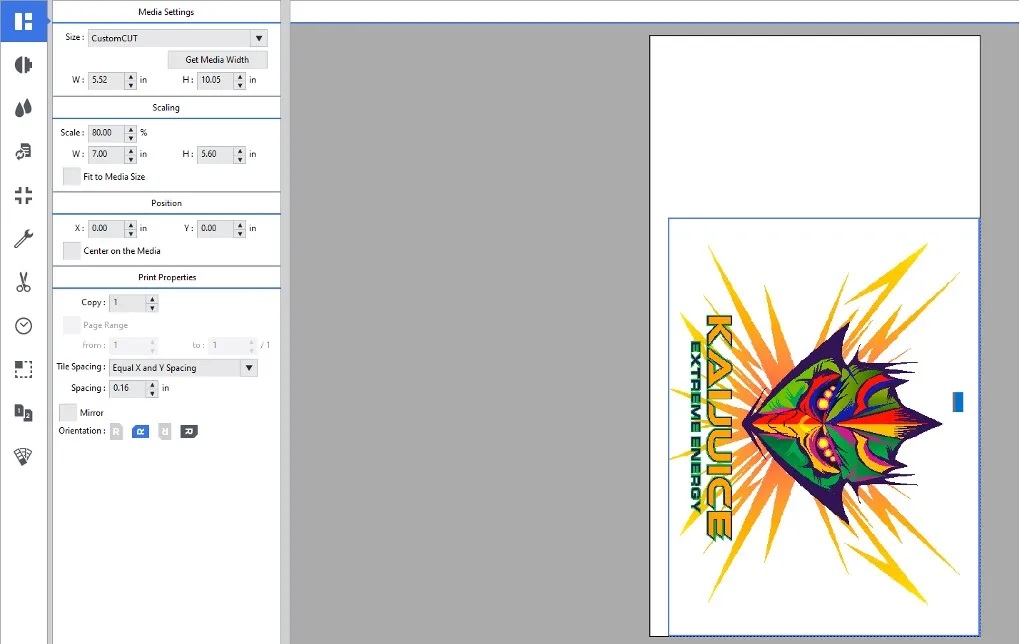

- Import your graphic into VersaWorks. Set your desired size, position, and quantity for print.

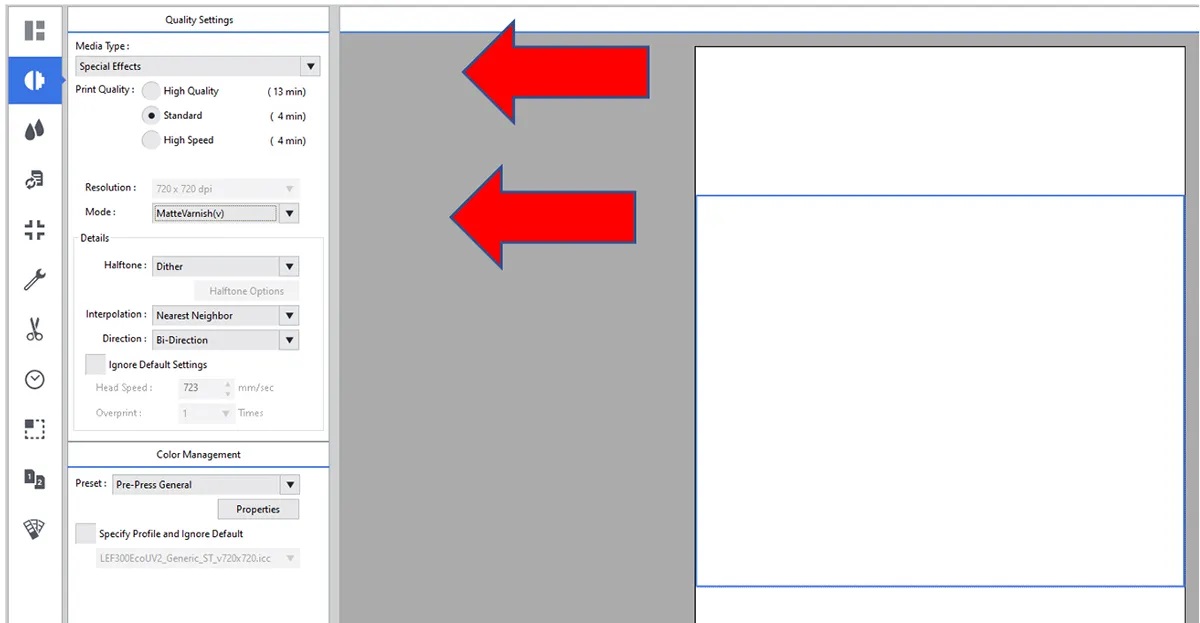

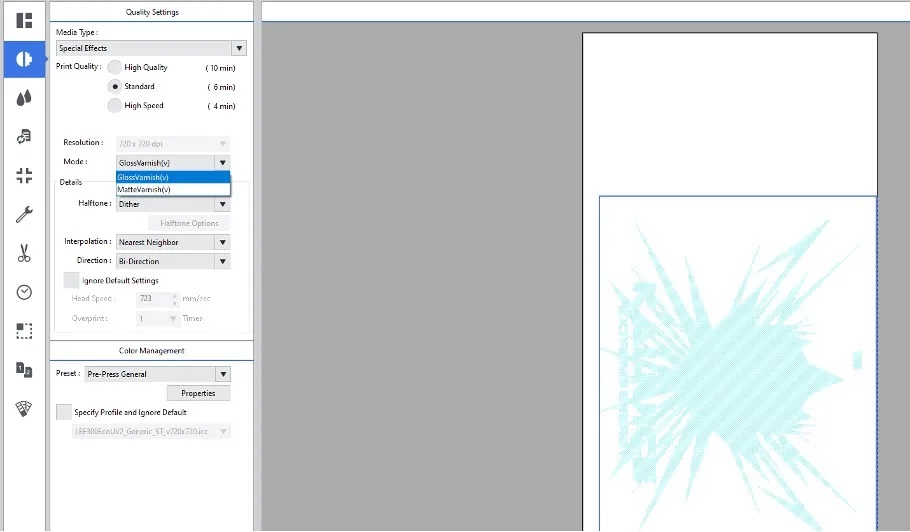

2. Select the Media Type as “Special effects,” and the Mode as “MatteVarnish.”

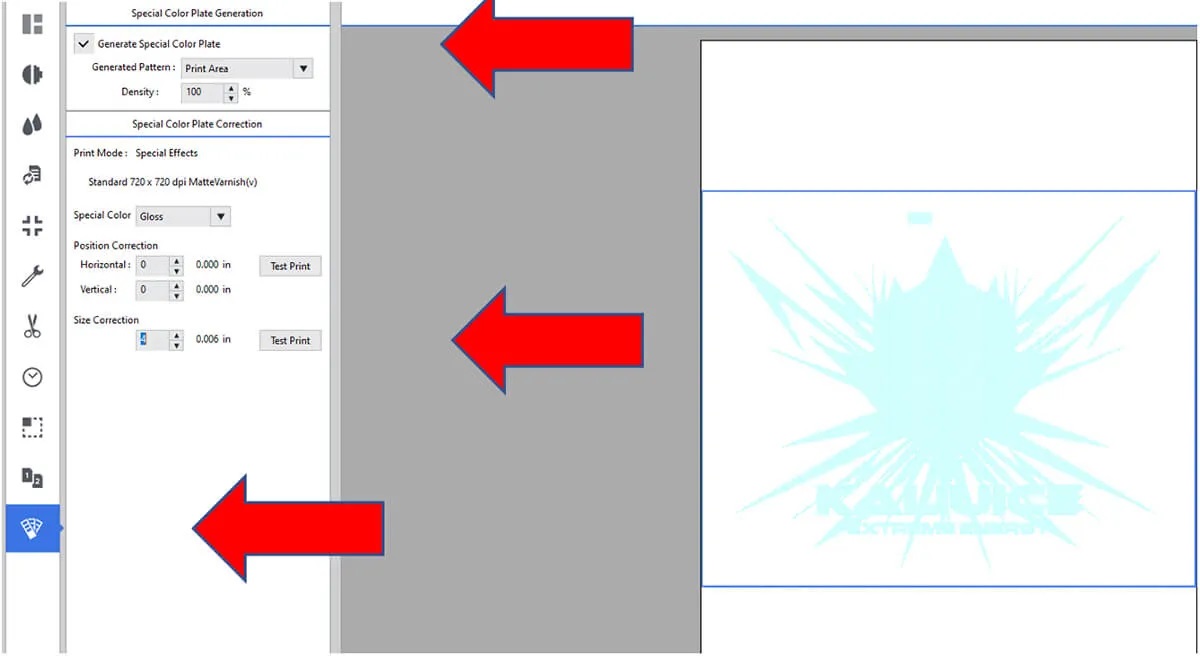

3. Next, go to the special color plate generator and select “Generate Special Color Plate.” Under “Size Correction,” move the number up, from + 2-6 (or even more than six, if desired, for heavy spread). This will expand the Gloss layer to produce a wider base than the CMYK layer. A -negative number will produce a choke, helpful when printing white under base.

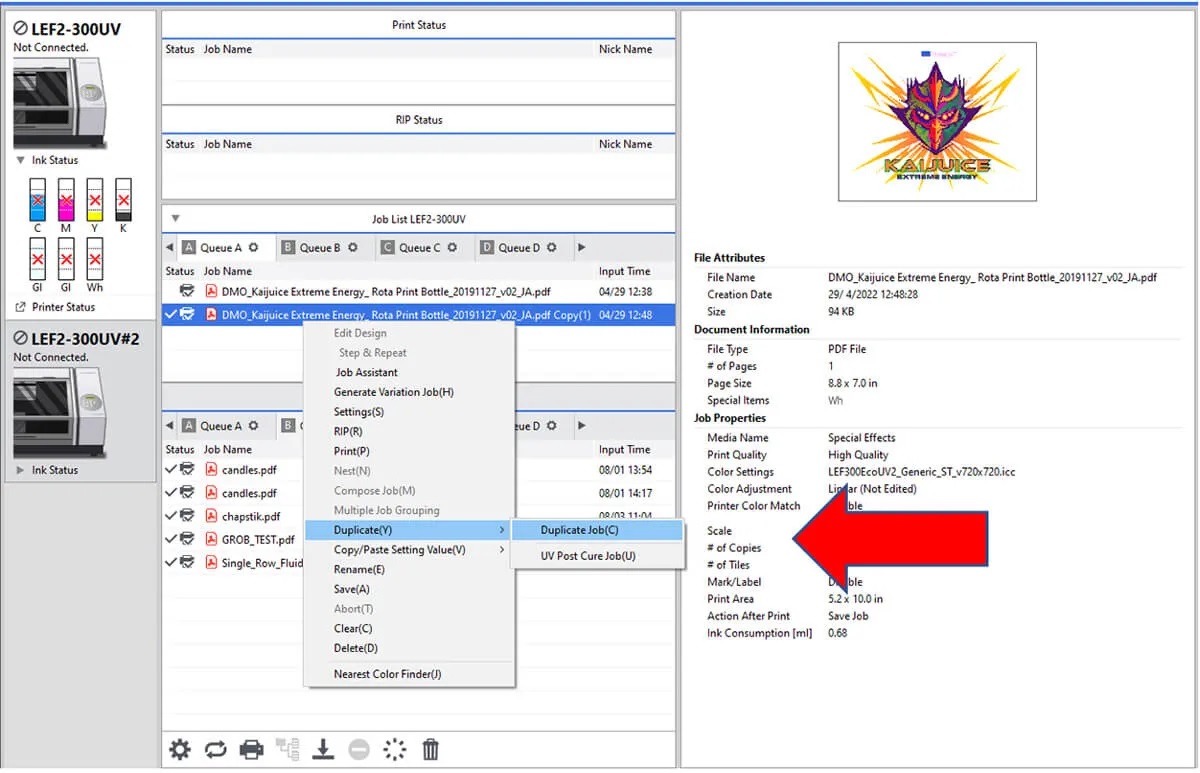

4. Press “OK” and return to main queue page. Now, we need to duplicate this file for additional printing. Two additional files are needed.

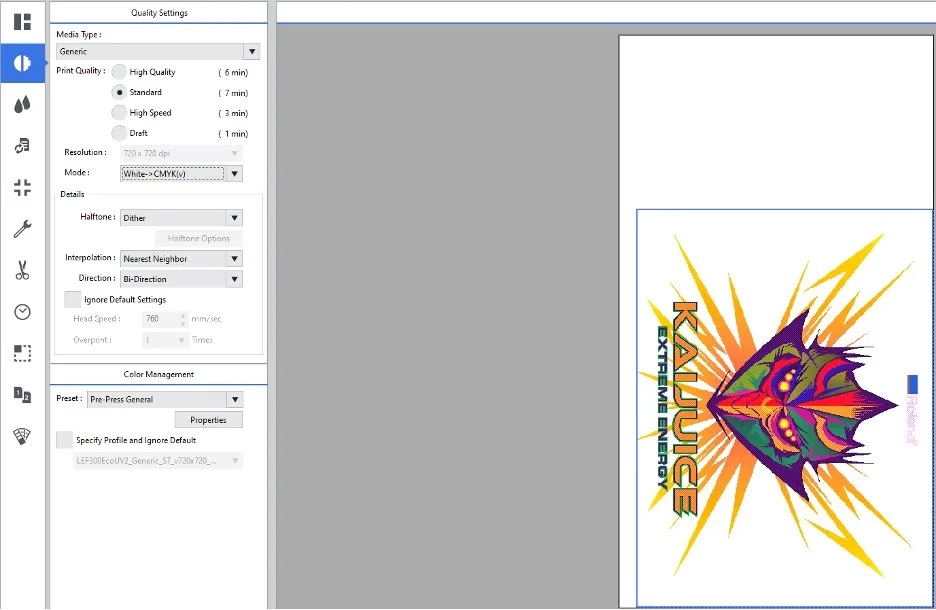

5. Open duplicated file # 1 and change the Media Type back to “Generic” (or ”Distance”), depending on print. If White is needed, change print mode to White CMYK. Select “OK.”

6. Open duplicated file # 2 and change Media Type back to special effects, then duplicate Step 3. You have a choice of Gloss or Matte. Once completed select OK.

You are now ready to print your encapsulated file.

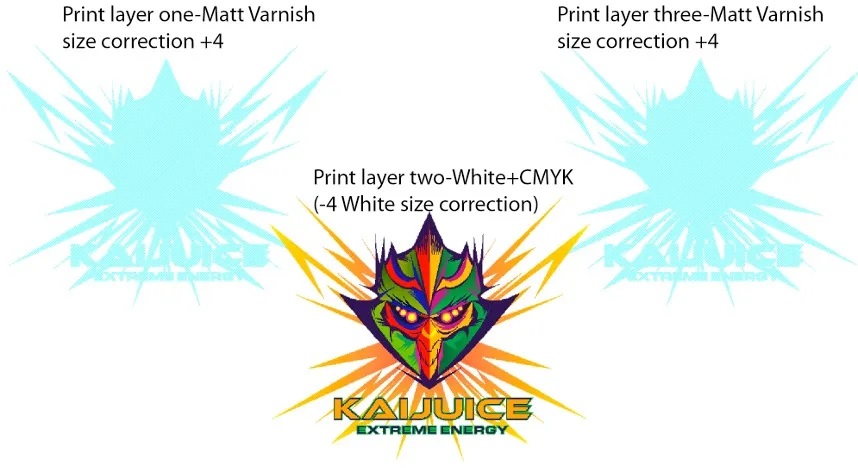

- Rip and print file one – Matte finish with a + 4pt ink spread

- Rip and print file two – White CMYK Note: If printing White CMYK, you will also need to generate a White plate, by selecting White CMYK, then going to the “Special” color plate generator as well. Keep in mind that a negative size correction for White will choke under the CMYK Ink.

- Rip and print file three – Second Gloss layer and encapsulating layer, Gloss or Matte finish

The result is an encapsulated print that is protected and has better adhesion as well as increased abrasion resistance.