Are you in the market for a Direct-to-Garment (DTG) printer? Is this your first venture into DTG printing? Even if you’re not a novice, a DTG printer has different requirements and processes than other printers.

The following blog post takes a look at some key questions to consider if you’re shopping for a DTG printer.

What will make up the majority of my DTG business?

You may associate DTG printers with printing onto dark or black t-shirts, and if that’s going to make up at least 70% of your business, then yes, buying a DTG printer with white ink is essential. You’ll need to print a white layer on your t-shirt first so the colored (CMY) inks will show up. If you can imagine the way people color on black paper, you can recognize the issue; when adding colors onto black paper, the blackness of the paper makes it very difficult to see any other color, except white. However, if you add color onto white paper, you’re able to easily see all the colors. Therefore, it’s only possible to recognize color additions on black paper unless you first add a white base color.

Now, if you’re interested in printing white to light colored products, there’s no need to have white ink. There are many t-shirts, tote bags, aprons, etc. that are white, gray, or light colored that don’t need an initial white layer of ink added.

There’s also another option for those who want to do dark or black t-shirt printing but don’t have white inks but may own screen printing equipment – screen print a base layer of white ink and then print your color on top of your white base using your DTG printer.

Example of screen print to DTG print workflow— screen print a base layer of white, then print color using your DTG printer.

Are there differences in prices for a CMYK DTG printer vs. DTG printer with white ink?

Yes, there is. Roland DG’s entry-level DTG printer doesn’t have white ink, and it’s designed for those who are new to DTG printing or adding DTG printing as an additional service to their core business. The list price is $3,495 and includes a finishing oven to cure the inks onto the fabric. DTG printing on fabrics require a finishing oven or heat press to set and cure the inks. Most DTG printers with white ink will start around $12,000 to $15,000, and you’ll need to get a heat press, if you don’t already have one. Other equipment to consider for printing with white inks include:

The VersaSTUDIO BT-12 is Roland DG’s entry-level DTG printer— the list price is $3,495 and includes a finishing oven to cure the inks onto the fabric.

What exactly is pretreatment and why should I do it?

Pretreatment is a liquid solution that’s typically vinegar based—thus the vinegar smell. It’s used for dark colored fabrics. It helps the inks bond to the fabric and improve wash durability. Make sure that you match the pretreatment with your DTG ink; what works with one brand of ink may not work well with another brand of ink.

This liquid pretreatment also works for white and light t-shirts, ensuring better prints and wash durability.

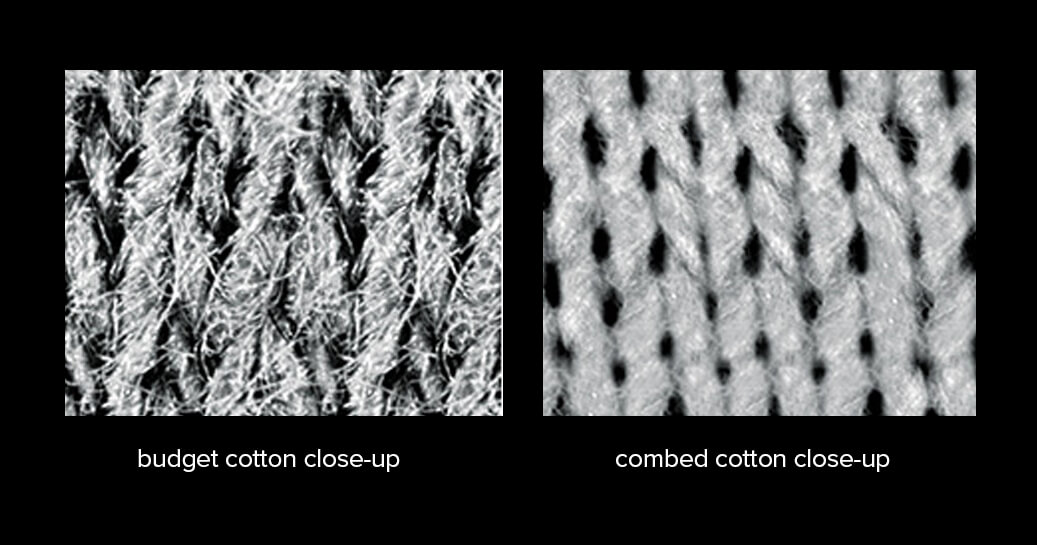

- Higher quality productions of cotton that are smooth have a tight weave to create a smoother surface for more inks to lay on

- The colors look better and are more durable in the wash

- The cotton doesn’t pill like the low-quality cotton fabrics— pilling makes the prints look “fuzzy” and dull

- Coupling a better fabric and more ink laydown contribute to better prints that do not require pre-treatment

Showing the differences in cotton quality— the higher quality “combed cotton” offers a better canvas for your ink to yield better print results

| 100% Ringspun Cotton T-Shirts

Wholesale Order Product Reference

|

|

| Gildan

o Softstyle® Series, i.e. 64000, G640 o Heavy Cotton o Hammer

|

Hanes

o Nano T 4980

|

| Fruit of the Loom

o 3931 o 61-422-0

|

American Apparel

o 2001

|

| Next Level

o 3600

|

Cotton Heritage

o 1082

|

| Bella Canvas

o 3001

|

Anvil

o 780

|

| Spectra Tees

o 3100

|

Keya

o MC 180

|

The images above illustrate how clogged print nozzles can result in print banding and poor print quality

Contact Us:

Content Courtesy : Roland DGA