You can take a vinyl cutter a long way, whether you’re making custom t-shirts or window lettering. However, at some point, you’ll get to a point where you need to upgrade your cutter and invest in your business. But you don’t want to buy a new cutter for the sake of it – you have to know if it’s something you need. So how can you tell when it’s time to upgrade your cutter? The following indicators should let you know.

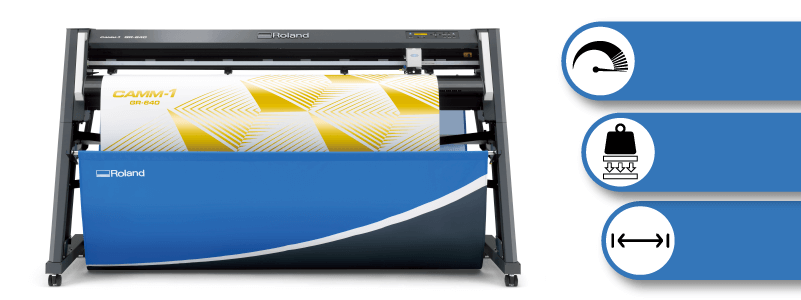

1. NOT FAST ENOUGH

Once your vinyl cutting venture takes off, you might find yourself struggling to keep up with an increased number of orders. There’s nothing worse than watching orders flood your inbox while you wait for your cutter to complete jobs.

If you often find yourself hanging around or making more cups of tea than you used to, it might be time to look for something with a faster cutting speed.

2. NOT ENOUGH CUTTING FORCE

For a lot of people, when they first get into cutting machines, they assume that their choice is limited to different colours of vinyl. It’s exciting to discover that you can also cut card stock, reflective vinyl, magnetic sheets, flock and a whole universe of other materials.

With such a wide variety of media available, you could be tempted to experiment with different applications. You might find yourself daydreaming about a hoodie with sparkly heat transfer vinyl or an intricate packaging design. Unfortunately, if your cutter just can’t manage thicker media, your ambitions could be cut short.

3. NOT WIDE ENOUGH

“You can cut small on a big cutter, but you can’t cut big on a small cutter”. This graphics industry adage still rings true, and for good reason. At Roland DG, we always hear from customers who wish they had simply bought a wider device in the first place. For obvious reasons, there’s just so much more that you can do with a wider cutter.

If you find yourself saying “no” to customers who want to create larger graphics like for shop windows or large vehicle decals, you’ll probably need to upgrade to a larger width. This also means that you’re not restricted by the available size of the media.

4. NO LAN CONNECTIVITY

If you can see your business growing in the future, it pays to get ahead of the game and install equipment that will meet the increased demand. Faster, wider cutters will contribute significantly, but that depends on your business. You might need more ways to boost your productivity.

With LAN connectivity, you can run multiple machines from the same hub, letting you centralise all your work. As a bonus, this also lets you control your cutter, or cutters, remotely. In larger premises, the designer might be in a different location to the cutting room, so a network connection lets them send their designs to the cutter.

5. IT HAS SEEN BETTER DAYS

When talking about Roland cutters, the words ‘bulletproof’, ‘invincible’ and ‘tough’ often come up. It’s true that these devices, properly maintained, will give you years of profit, but every mechanical device can suffer wear and tear.

Over time, your pinch rollers and cutting strip will degrade and the rigours of constant production will take their toll. Although the components are easy to replace, you could consider this as a wake-up call, letting you know that it’s time to consider other options.

We know how easy it is to get attached to a device that has only ever given you 100% great results. Heart-breaking though it may be, everyone moves on to bigger and better things eventually. It’s up to you to look to the future and picture the business you want, not just the one you have now. With more advanced equipment, there’s less holding you back from making your dreams a reality.