Investing in a UV flatbed printer can open up fantastic new opportunities for an already established wide format printing business. You already know the many benefits: whether it’s printing directly onto a huge range of rigid and flexible media, the new products you’ll be able to produce, or the quantities you can produce them in. Producing high-value product customizations, custom packaging , interior decorations or anything else that no one else has ever thought of has never been so fast, versatile and profitable.

However, with so many options available, choosing the right UV flatbed printer for your specific needs can be a difficult choice. This is an investment, so your new printer must be able to meet your current and future needs.

1: Evaluate your production volumes

UV printers are available in different sizes and print speeds, based on different productivity requirements. The beauty of digital printing is the ability to print on demand – you can only produce what you sell. So while waste and inventory aren’t an issue here, you still need a device that can meet demand without surplus.

- Study consumer trends and identify your customers’ willingness to pay for your products. Analyze your competition and their prices, product range and market share. Identify gaps in the market that could be exploited.

- Develop optimistic, realistic and pessimistic sales forecasts. Calculate manufacturing costs, including materials, labor, overhead and other costs.

- Evaluate the potential to increase production volumes as demand grows, taking into account additional requirements for equipment, workspace and personnel.

Small businesses and those with lower volume needs will likely be able to make do with a desktop or benchtop model. They offer a compact footprint and an affordable price, while being able to produce a high-quality result at professional speeds. However, if you plan on high-volume production or larger jobs, you’ll likely want to opt for larger flatbed printers that offer larger print areas, faster print speeds, and improved features to keep up with a high workload.

2: Consider your maximum print size requirements

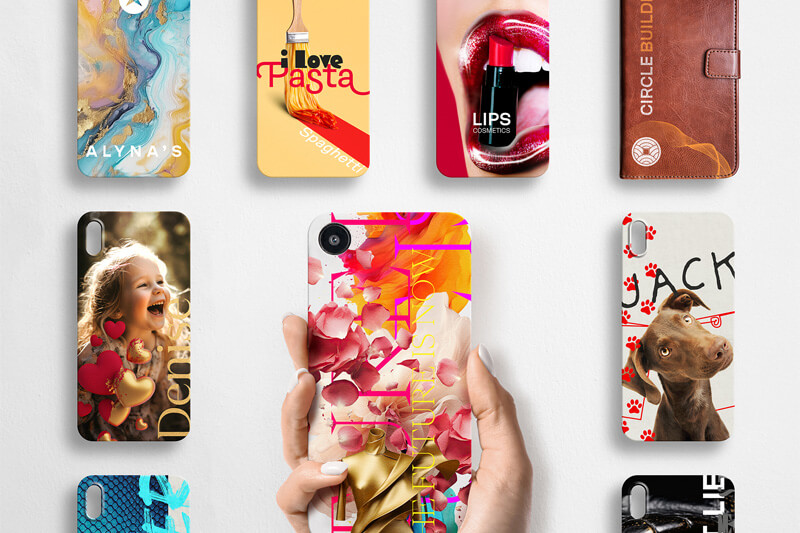

Likewise, knowing what products you plan to offer (now and in the future) will be crucial in choosing the size of peripheral you need. Small items such as promotional USB sticks or phone cases can be made on a smaller flatbed printer and for many businesses this can be ideal. But be sure to also consider any products you might produce in the future. Likewise, if you plan to print larger signage , POP displays, or other large graphics, you’ll need a flatbed printer with a print area that can cover these sizes. If you have already considered this and are concerned that your items are too large, consult a printing specialist first as some peripherals can be modified with factory components to increase the print height.

3: Evaluate the versatility of the supports

One of the main advantages of UV flatbed printing is the ability to print directly onto a wide range of rigid and flexible media, from metal and wood to glass and leather . By using primer, there are very few materials that you can’t print on . So, in addition to the products you plan to produce and the materials you want to print them on, be sure to also evaluate the following aspects:

- Material Compatibility – Think about the durability, weight, or aesthetics of the media and make sure the device can handle what you want to produce.

- Cost Optimization – Depending on the application, some media may be more cost-effective than others. A versatile printer allows you to choose the most economical support suitable for each job, optimizing production costs.

- Sampling – If a customer requests the creation of prototypes or samples using different materials, a printer that can handle various media allows you to test and showcase your designs on intended production materials.

- Future Adaptability – As new materials and media enter or become popular on the market, a versatile printer will be able to adapt to these changes, allowing you to stay competitive.

4: Maximum print quality and color accuracy

Pay particular attention to the print resolution, ink configurations, and color management features offered by different models. Powerful color management tools and ICC profiling capabilities ensure accurate and consistent color reproduction across various media and even peripherals. If you produce branded signage and banners for a client, being able to offer promotional merchandise with an exact color match will be a great advantage.

5: Consider workflow automation and software integration

Printer manufacturers are working hard to simplify printing processes and flatten the learning curve as much as possible. Many peripherals come with features that allow for seamless integration with your existing workflow and software. From intuitive interfaces that can simplify job setup to powerful yet intuitive RIP software packages, such as Roland DG’s VersaWorks 6 , these features can significantly reduce manual intervention and errors while improving overall efficiency.

If you can purchase a new UV flatbed printer with the same branding as your other peripherals, not only will you already be familiar with many of their features, but these peripherals often work with the same systems or allow for integration. Roland DG Connect PrintAutoMate , for example, allows users to automatically map incoming jobs to their templates and output devices for high-volume printing; This means you can automate printing 6 phone cases on a small flatbed printer and 10 electronic panels on a larger flatbed.

6: Evaluate current operating costs

While the initial cost of a UV flatbed printer is a significant investment, it is essential to also consider the ongoing operating costs. Factors such as ink consumption, printhead life, and maintenance requirements can vary greatly between different models and manufacturers.

Research and compare these costs carefully, as they can have a substantial impact on your company’s overall profitability over the life of the printer. There are solutions available, such as Roland DG connect , that offer information on various business processes, such as profitability and job costs, as well as monitoring and checks on the status of peripherals to minimize downtime.

7: Don’t underestimate reliability and technical support

Downtime can be very costly, so a reliable peripheral is critical. While we always hope that everything goes as planned, it’s always best to plan for the unexpected. In addition to device reliability, ensure you receive timely, quality service and support.

Manufacturers can offer comprehensive warranties, readily available replacement parts, and responsive technical support to minimize potential disruptions and ensure maximum printer productivity. Roland DG Care is an industry-leading warranty plan that offers comprehensive coverage with no hidden costs, genuine Roland parts, fast call response and more.

8: Future-proof your investment

We’ve said it before, but it bears repeating: Consider your potential for future growth. Anticipate potential increases in production volume or changes in application requirements, both in terms of what you can produce and what the customer will require. Needs change, as does your ability to meet them.

Choosing an upgradeable system can help future-proof your investment, allowing you to adapt to changing market demands without the need for a complete overhaul of your equipment.

To conclude

Choosing to start using a flatbed UV printer is exciting; but it’s not always easy to choose the right one. The number of options available is to your advantage, as long as you do careful planning, evaluate your specific needs, consider the above factors, and talk to the experts. You are sure to find the perfect solution to advance your printing business.

If you would like further information on the contents of this article, our experts will be happy to help you.